Magnetic Testing

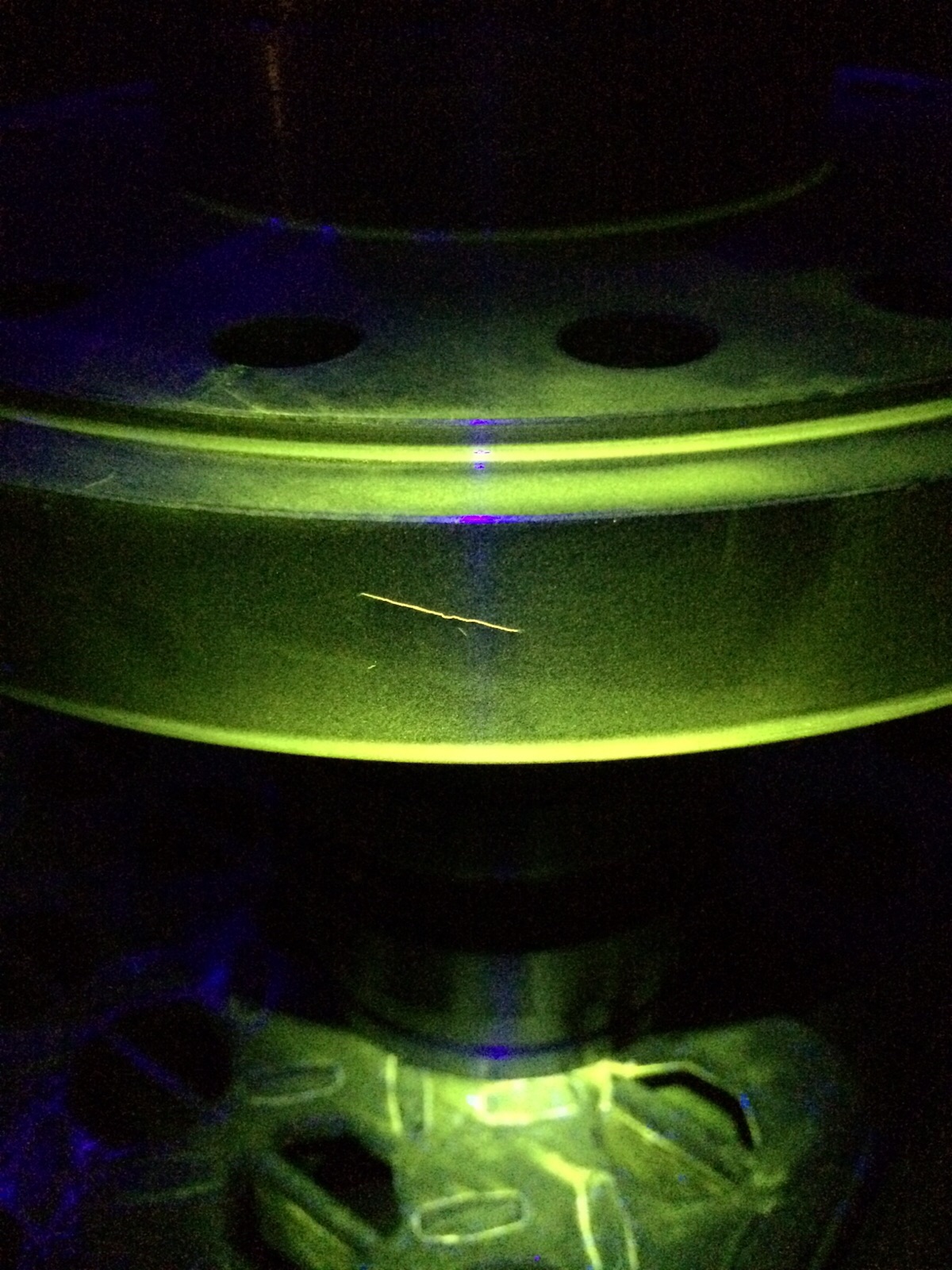

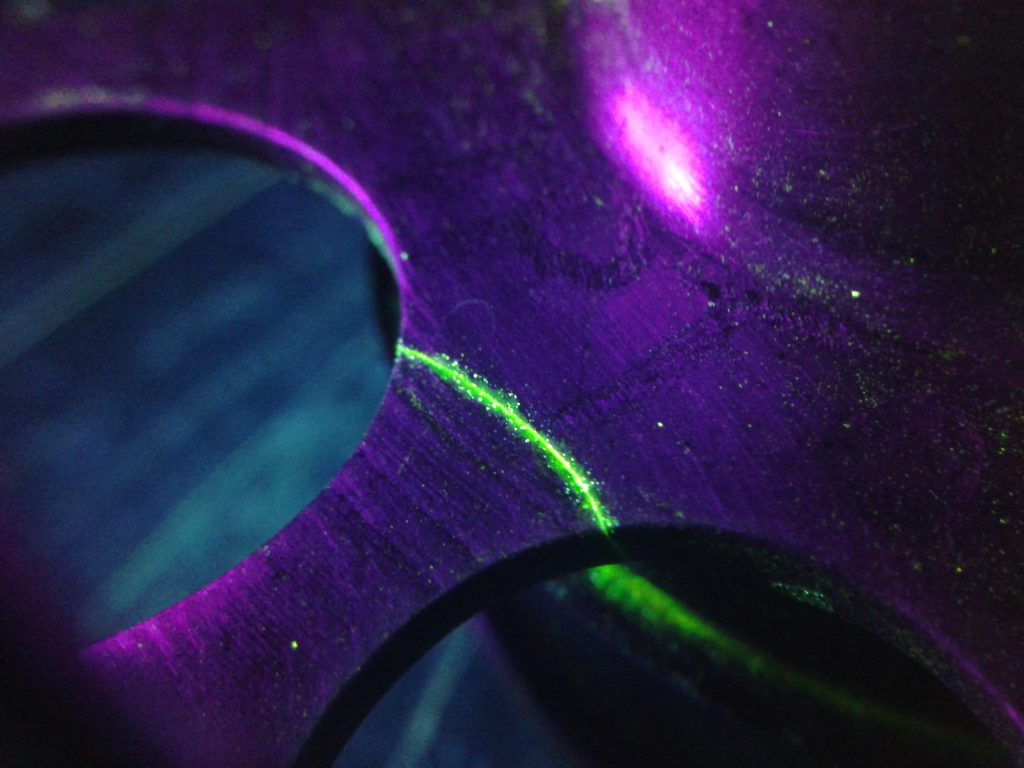

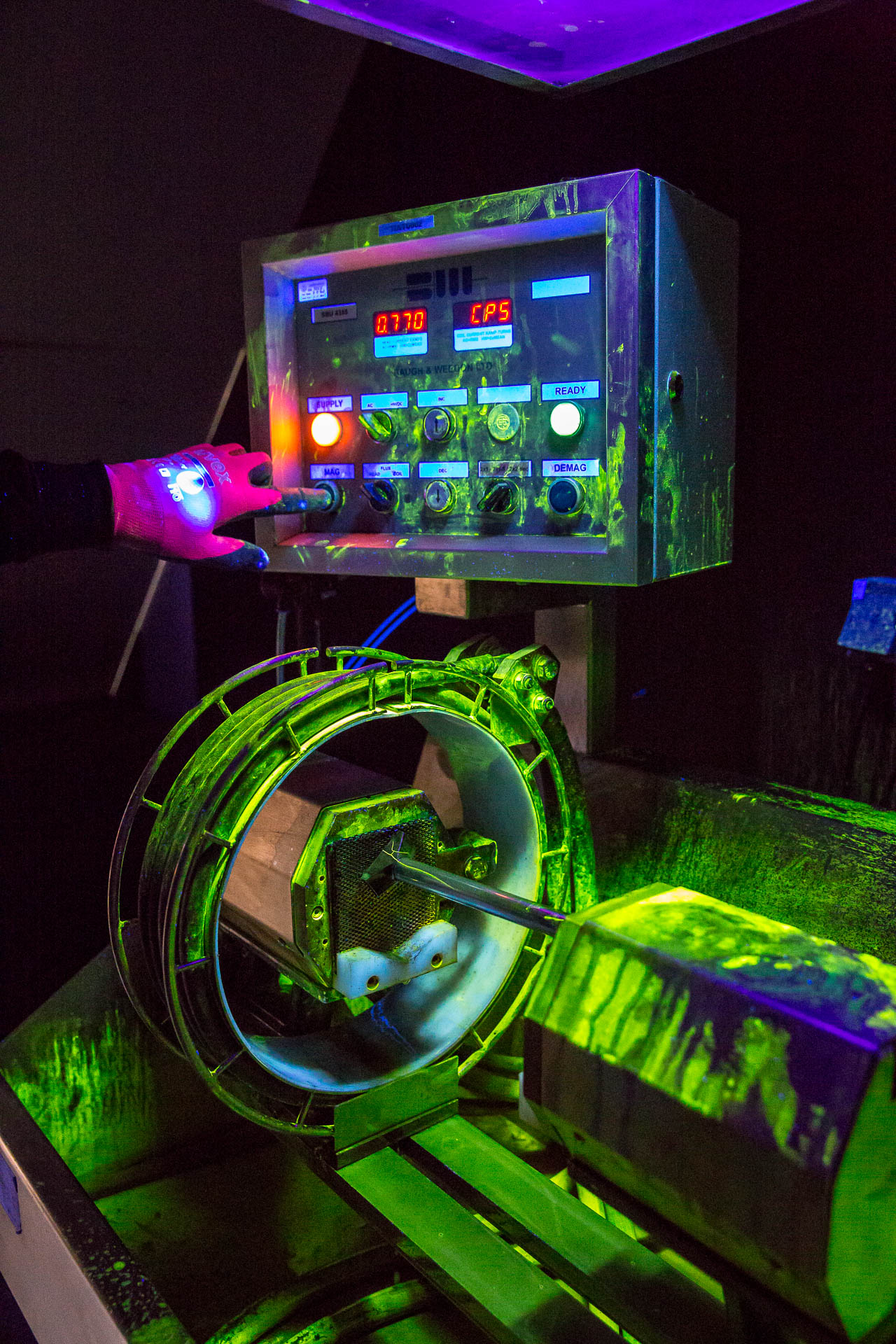

Magnetic testing (MT or MPI) is a NDT method in which a magnetic field is generated in magnetisable materials. This can detect defects on and/or just below the surface. Performed on a magnetic bench under UV light, magnetic testing is known as a test method that allows fast and reliable determination of very small defects (sensitivity).

Before starting the inspection, the surface must be cleaned: coating, grease and dirt should be removed, and a special paint may be applied to make the defects more visible.

A magnetic field will be generated. This will create a leakage field at the location of a defect. On the surface, iron particles are then applied in wet or dry form and the leakage field will attract these iron particles. Because of the colour difference between the attracted iron particles and the background, the defect will be visible on the surface, this is called an indication. This indication is assessed by the inspector according to the required standard and/or specification. The surface indication is assessed according to the required standard, resulting in acceptable or unacceptable.

Most magnetic testing in aviation is carried out under UV light conditions to make small defects visible (higher sensitivity). For larger quantities of uniform products (such as axles, gears and bolts), the UV test is often combined with a magnetic bench. For each application, the best choice of magnetization method should be made in order to perform an optimal examination.

The inspectors are trained according to EN4179.

Tests may take place in accordance with all applicable standards and requirements of the principals and ASTM-E-1444.