Penetrant Testing

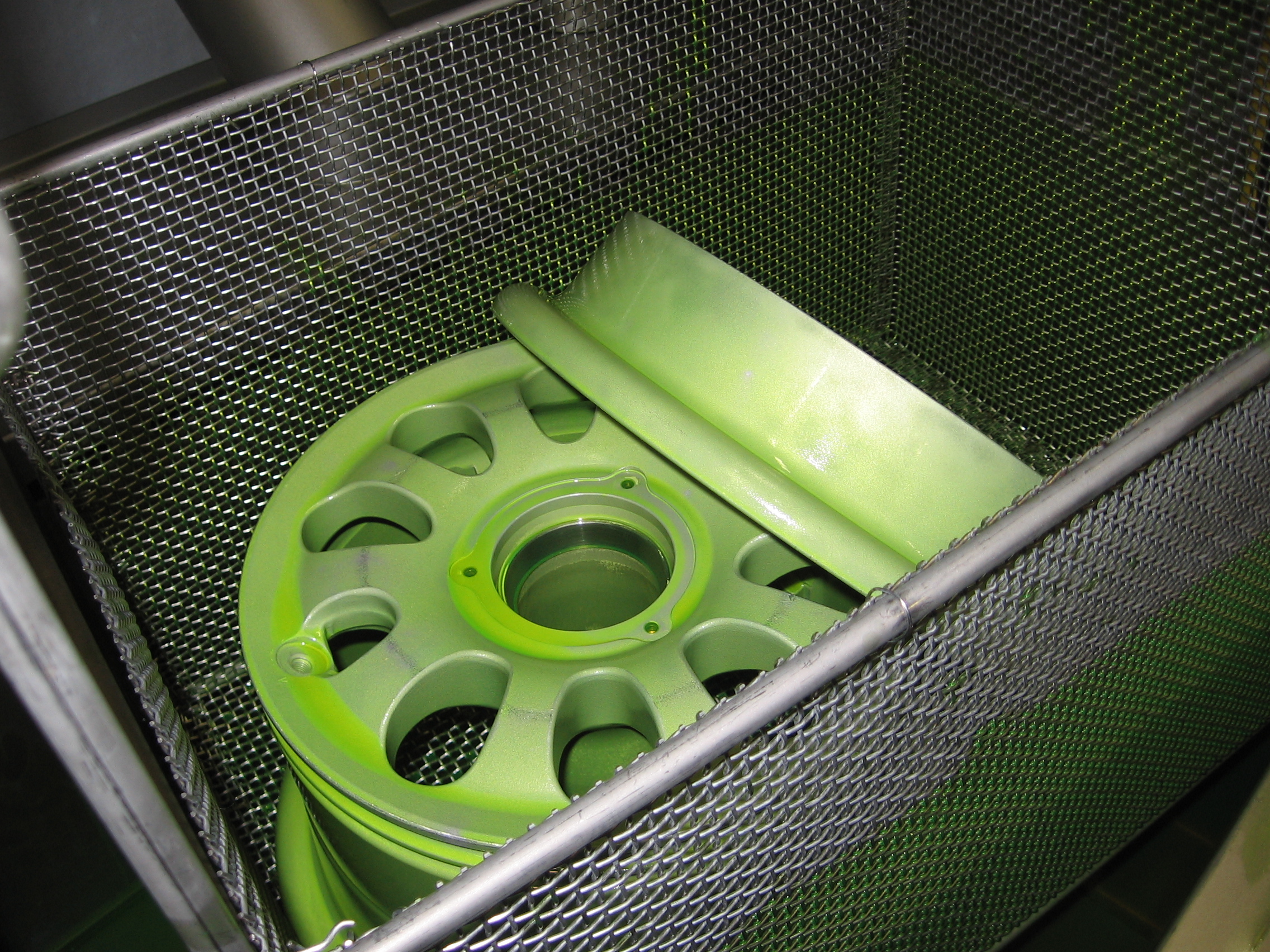

Penetrant Testing (PT or FPI) is an NDO method in which a penetrating liquid is applied to the surface. Surface defects will be visible after the expiration of the penetration time and the application of a contrast powder.

Before starting the test, the surface must be cleaned very carefully: paint, grease and dirt must be removed, after which the penetrant liquid can be applied.

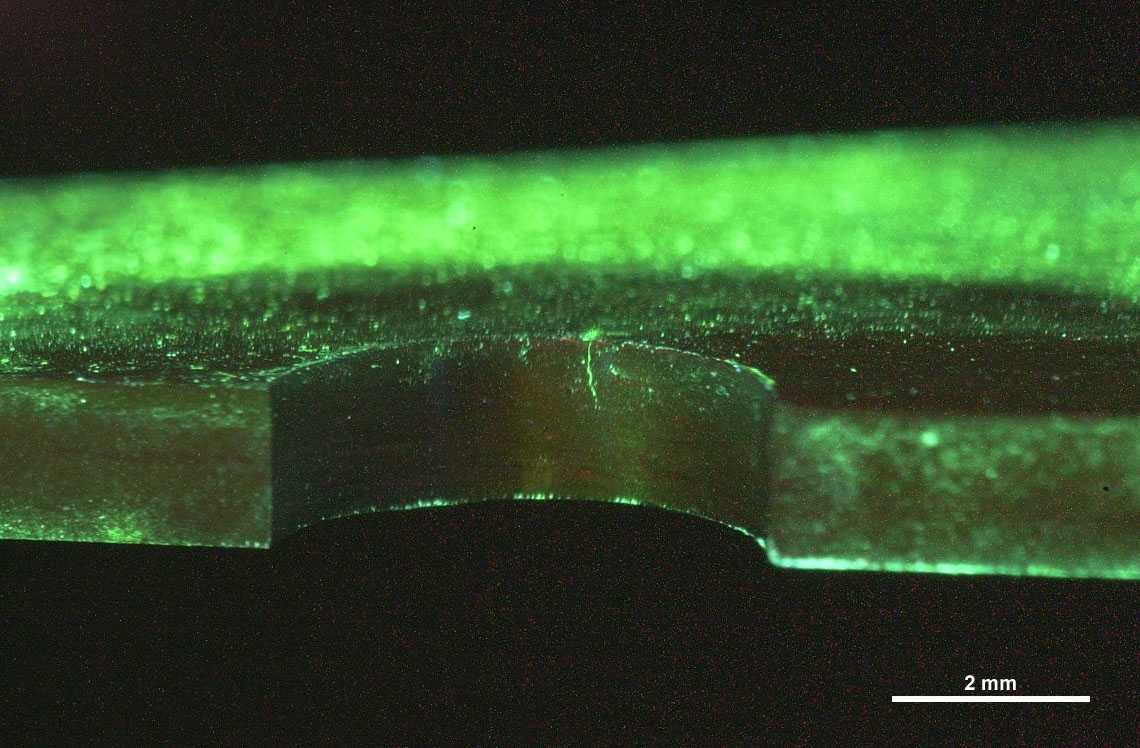

This fluid slowly penetrates surface defects by means of the capillary action.

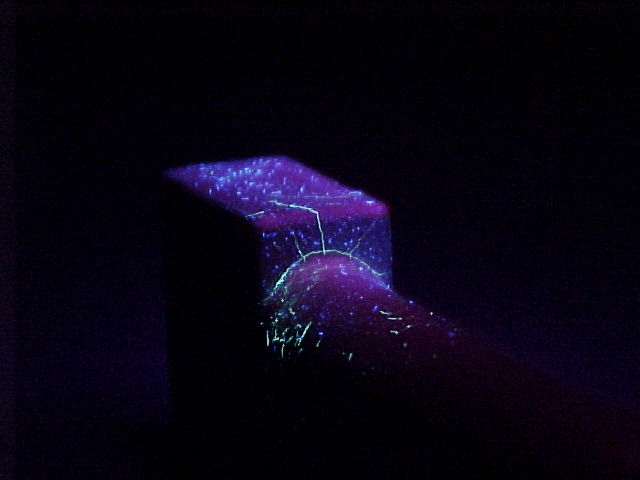

After removing the excess penetrant fluid from the surface and applying a contrast powder (developer), the indication of the defect will be visible.

This indication is assessed by the inspecotor according to the required standard and/or specification. The surface indication is assessed according to the required standard, resulting in acceptable or unacceptable.

Most penetrant testing in aviation is carried out under UV light conditions to make small defects visible (higher sensitivity).

For each application, the best choice of penetrant process should be made in order to perform an optimal examination.

The inspectors are trained according to EN4179.

Tests may take place in accordance with all applicable standards and requirements of the principals and ASTM-E-1444.